Cyclic Synchronous Position Control¶

The position control modes allow the EtherCAT master to send desired positions to the servo drive. The drive will make sure these position values are reached by the motor (if the motor is physically able to do so).

In this mode, the trajectory generator is located in the control device, not in the servo drive. In a cyclic synchronous manner, it provides a target position to the drive device, which performs position control, velocity control and torque control.

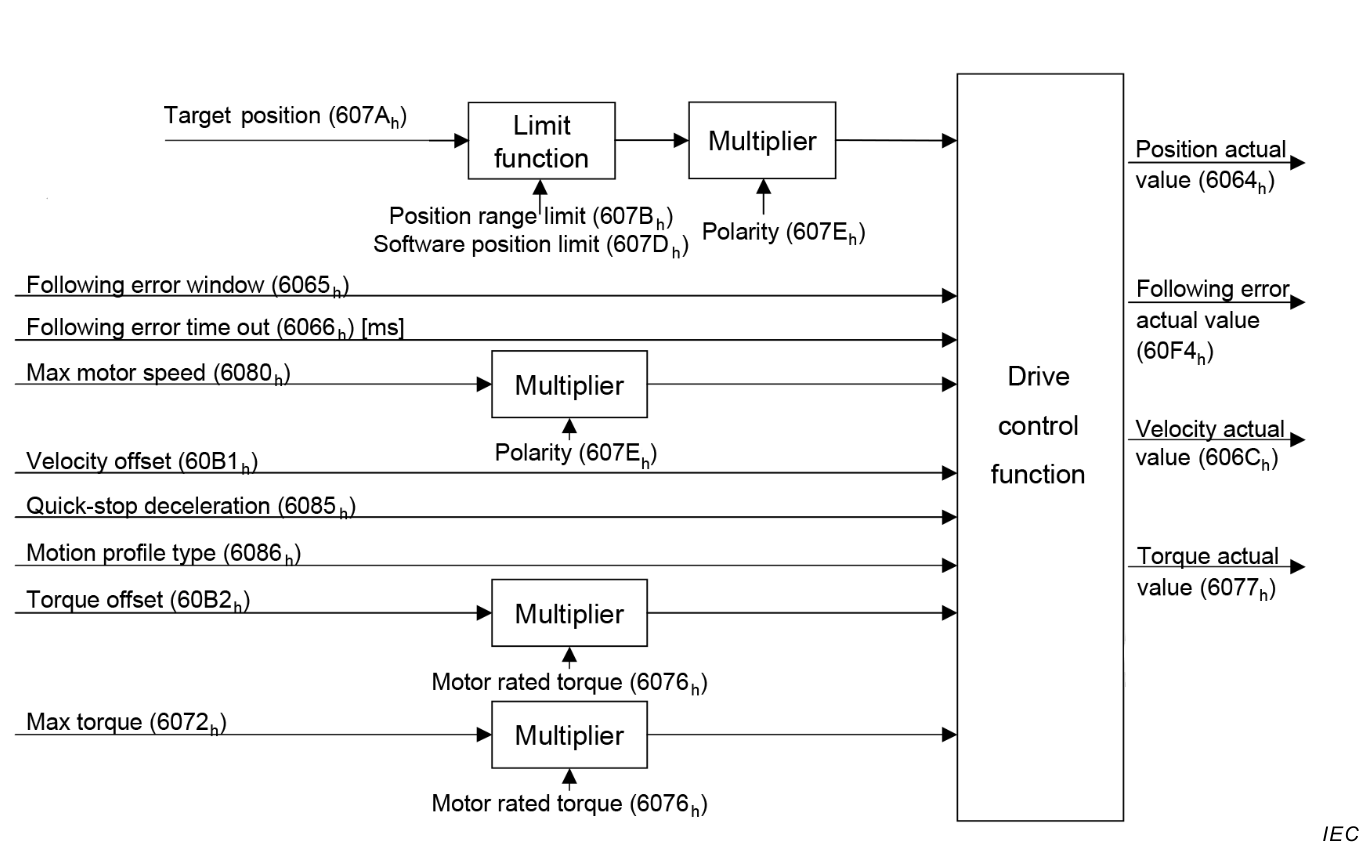

The figure above shows the inputs and outputs of the drive control function. The input values (from the control function point of view) are the target position as well as an optional velocity offset and an optional torque offset used for feed forward control. Especially in a cascaded control structure, where a position control is followed by a velocity or torque control, the output of the position control loop is used as an input for further calculation in the drive device. Limit functions can be used to restrict the range of values to avoid unintended positions. The drive device monitors the following error.

The target position is interpreted as absolute value. The position actual value is used as mandatory output to the control device. Further outputs are the velocity actual value and torque actual value. The following error actual value is used as an additional parameter. See Control supervision for details.

Three control loops are implemented for position control: